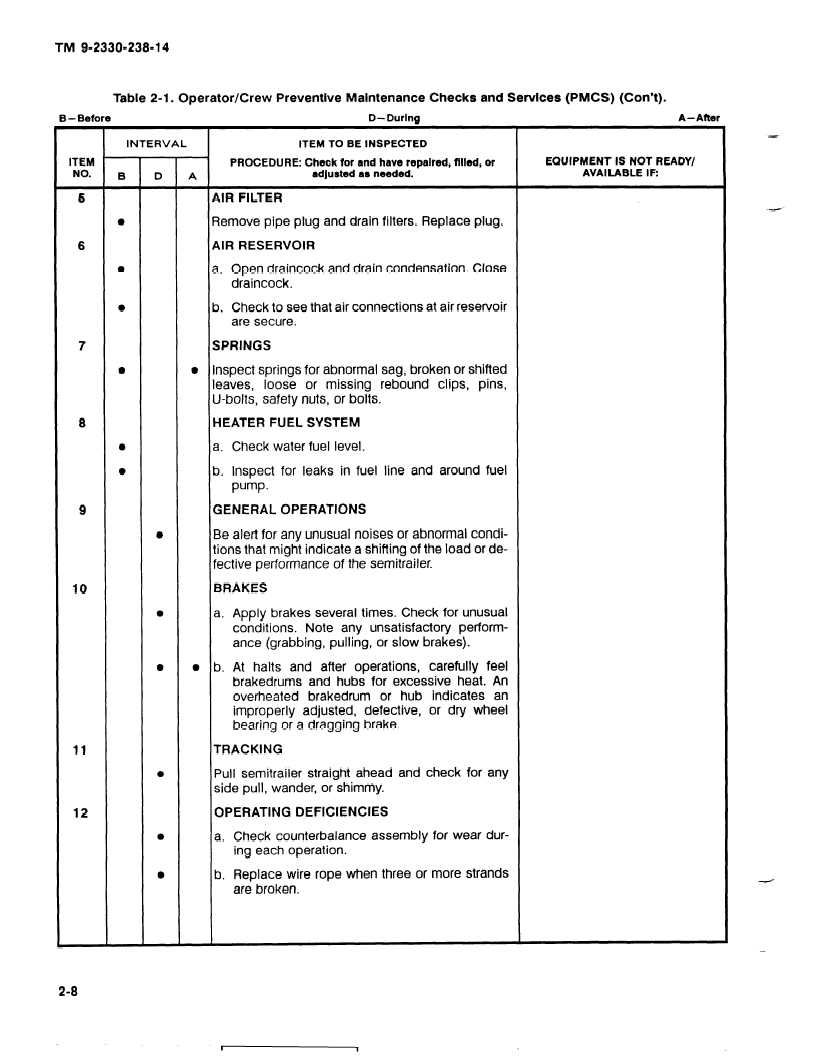

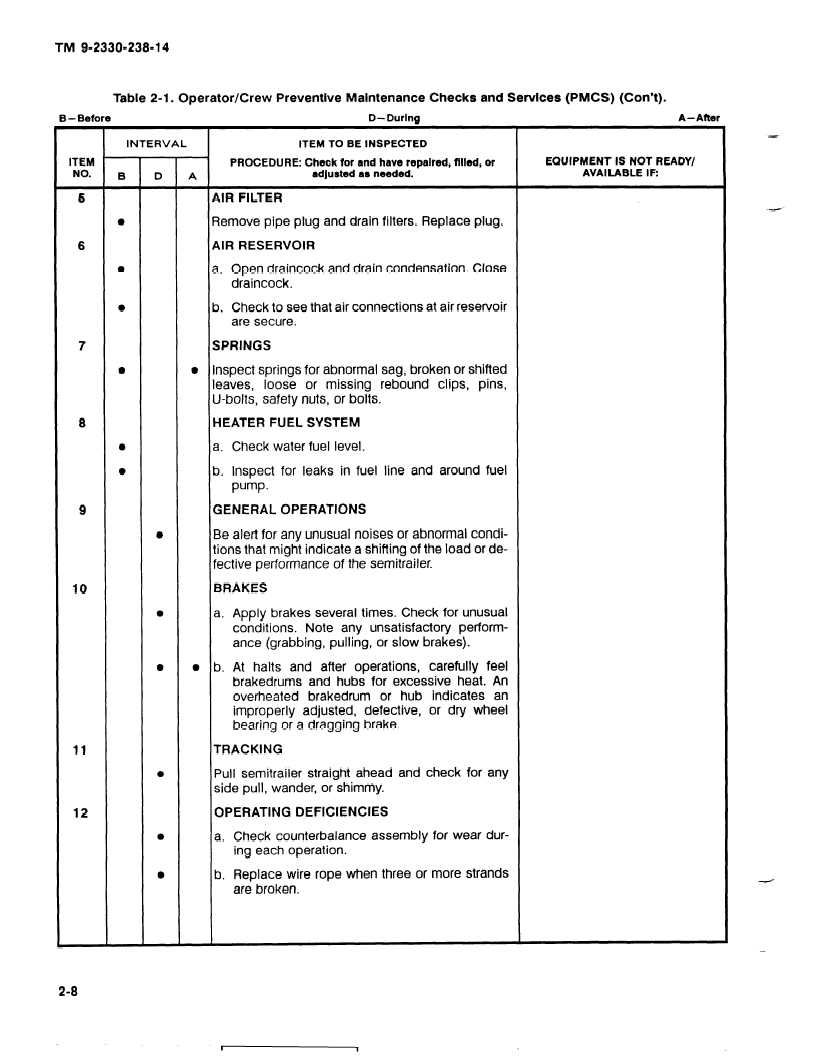

TM 9-2330-238-14

Table 2-1. Operator/Crew

Preventive

Maintenance

Checks and Services

(PMCS)

(Con’t).

INTERVAL

ITEM TO BE INSPECTED

ITEM

PROCEDURE:

Check for and have repaired, filled, or

EQUIPMENT

IS NOT READY/

NO.

B

D

A

adjusted as needed.

AVAILABLE

IF

5

AIR FILTER

l

Remove pipe plug and drain filters. Replace

plug.

6

AIR RESERVOIR

l

a. Open draincock

and drain condensation.

Close

draincock.

l

b. Check to see that air connections

at air reservoir

are secure.

7

SPRINGS

l

l

Inspect springs for abnormal

sag, broken or shifted

leaves,

loose

or missing

rebound

clips,

pins,

U-bolts,

safety nuts, or bolts.

8

HEATER FUEL SYSTEM

l

a. Check water fuel level.

l

b. Inspect

for leaks

in fuel line and around

fuel

pump.

9

GENERAL

Operations

l

Be alert for any unusual noises or abnormal

condi-

tions that might indicate a shifting of the load or de-

fective performance

of the semitrailer.

10

BRAKES

l

a. Apply brakes several times, Check for unusual

conditions.

Note

any

unsatisfactory

perform-

ance (grabbing,

pulling,

or slow brakes).

l

l

b. At halts

and

after

operations,

carefully

feel

brakedrums

and hubs for excessive

heat. An

overheated

brakedrum

or

hub

indicates

an

improperly

adjusted,

defective,

or dry wheel

bearing or a dragging

brake.

11

TRACKING

l

Pull semitrailer

straight

ahead

and check

for any

side pull, wander, or shimmy.

12

OPERATING

DEFICIENCIES

l

a. Check

counterbalance

assembly

for wear dur-

ing each operation.

l

b.

Replace

wire rope when three or more strands

are broken.

2-8