TM 5-3825-230-14&P

c.

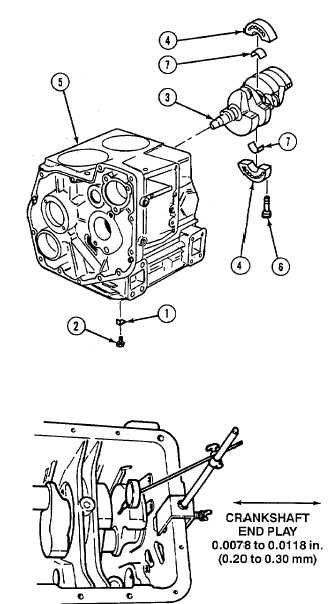

Installation.

(1)

Coat all parts with clean engine oil.

NOTE

•

Be

sure

when

bearings

are

installed, they are not covering

lubrication passages.

•

Center supports are beveled. Be

sure to install supports so they

match bevels on crankcase.

•

Ensure that bearings do not bind

on shaft.

(2)

Install center support bearings (7), center

supports (4), and two screws (6), on shaft

(3). Tighten to 22 lb-ft (30 N•m) using a

torque wrench and 6 mm hex head

socket.

(3)

Install crankshaft (3) in crankcase (5).

(4)

Install screw (1) and safety plate (2) using

a ratchet and 17 mm socket.

(5)

Install rear support (para 5-16).

(6)

Install front support (para 5-15).

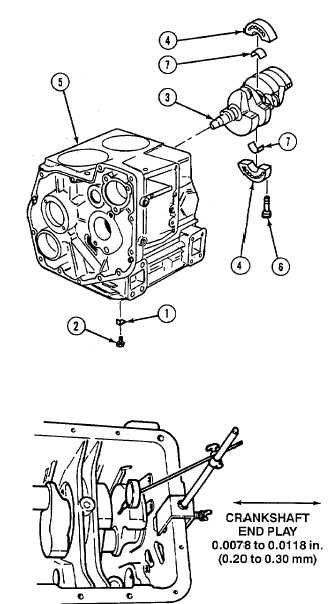

(7)

Check crankcase end play by:

(a)

Mount dial indicator as shown on

crankcase

with

needle

against

crankshaft counter weight.

(b)

Move

crankshaft

fully

towards

flywheel, then fully towards drive

end. Crankshaft endplay (move-

ment) should be between 0.0078

and 0.0118 in. (0.200 to 0.0300

mm).

5-29