TM 5-3820-245-14&P

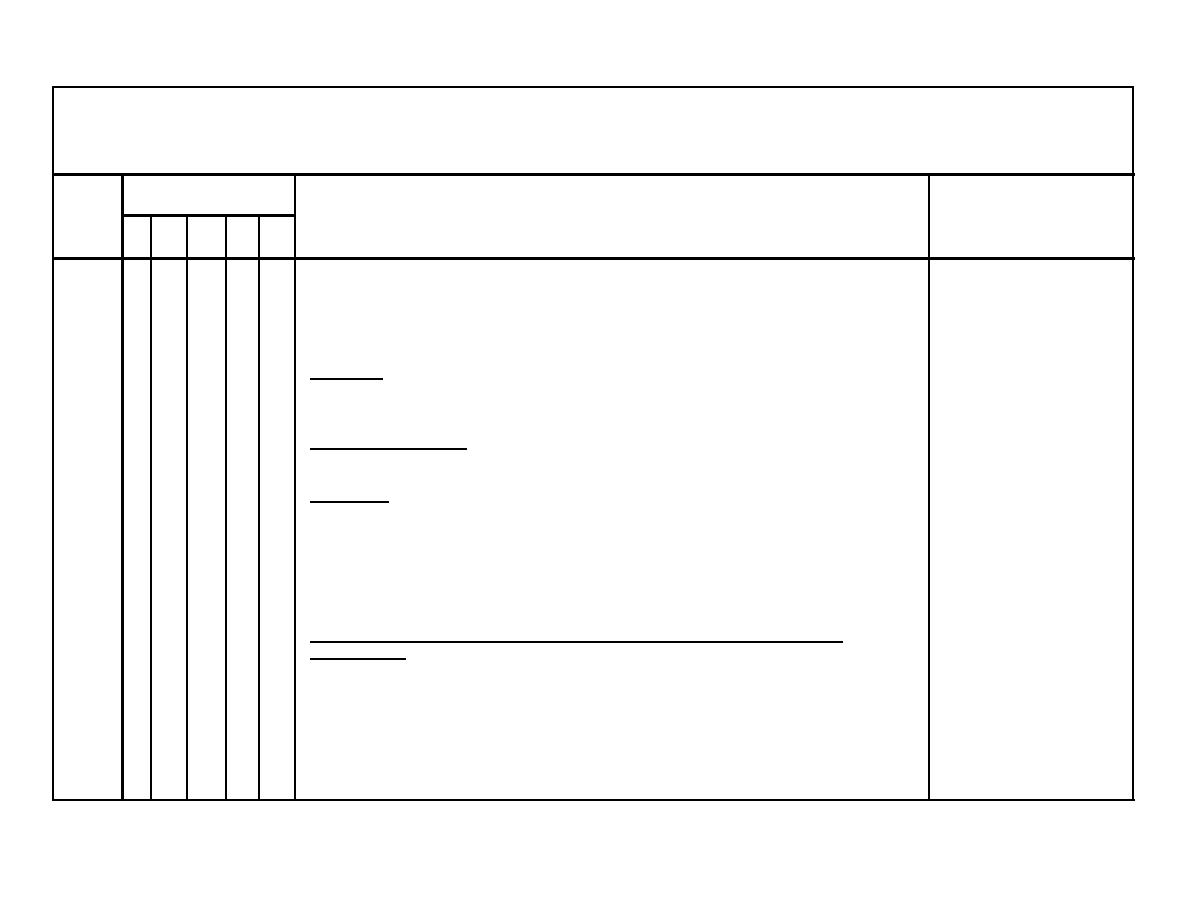

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B - BEFORE

D - DURING

A - AFTER

W - WEEKLY

M - MONTHLY

AUGER, EARTH, SKID MOUNTED MODEL 270-9

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO

PROCEDURE:CHECK FOR AND HAVE REPAIRED,

READY/AVAILABLE IF:

B

D

A

W

M

FILLED, OR ADJUSTED AS NEEDED

PERFORM WEEKLY AS WELL AS BEFORE PMCS IF:

a. You are the assigned operator but have not operated the unit since the

last weekly.

b. You are operating the equipment for the first time.

1

GENERAL

Look for evidence of fluid leakage (oil, fuel, coolant).

Class III leaks are found or

any fuel leakage.

2

ENGINE CRANKCASE

Check dipstick for proper level.Add oil as necessary to full mark.

3

RADIATOR

WARNING

Radiator cooling system is pressurized. Remove cap slowly and

only when engine is cool or painful burns could result.

Check coolant level. Add coolant as required. (Level should be approxi-

one inch from bottom of filler neck).

4

CONTROLS AND INSTRUMENTS (CHECK FOR PROPER INDICATION AND

OPERATION)

a. Engine coolant temperature gauge 160-1850F (71-850C).

b. Engine oil pressure gauge 18 psig at 1200 rpm (idle speed).

c.

Ammeter slight (+) charge.

d. Tachometer/hours meter 550 rpm - idle, 2500 rpm - max

Change 1 43