TM 5-3820-245-14&P

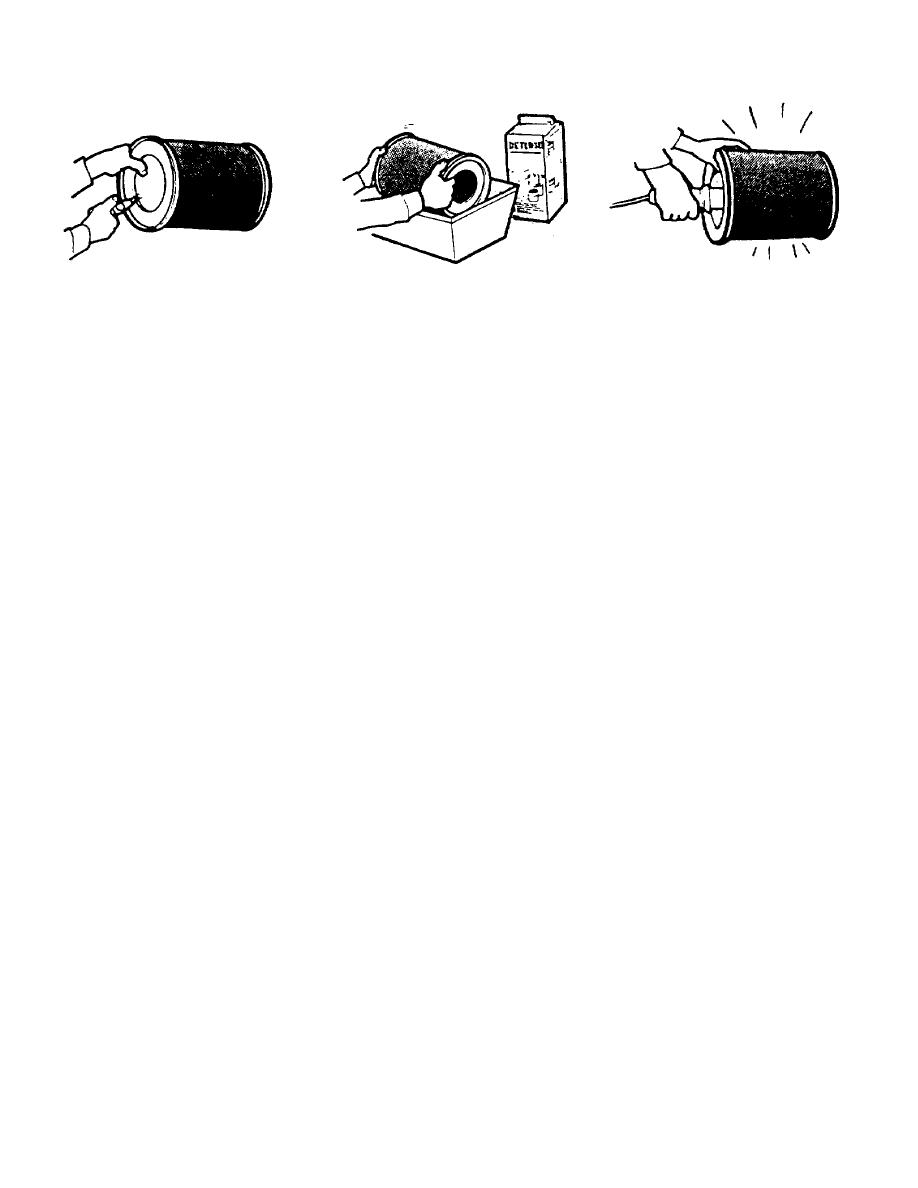

Compressed Air

Washing

Inspection

Direct air through

1. Soak element 15

Place bright light

element in the

minutes or more in

inside element and

direction opposite to

Donaldson D-1400 and

rotate element slowly.

normal air flow

water solution. See

If any rupture, holes

through the element.

carton for full

or damaged gaskets

Move nozzle up and

instructions.

are discovered -

down while rotating

2. Rinse until water

replace.

element. Keep nozzle

is clear (Maximum

at least one inch from

water pressure

pleated paper. Maximum

40 P.S.I.)

air pressure to prevent

3. Air-dry or use

damage of element is

warm flowing air,

100 P.S.I.

maximum 160F. Do not

use compressed air or

light bulbs.

GENERAL SERVICE TIPS

The air cleaner should be inspected periodically to maintain maximum engine protection and maximum service life. These

inspections should include the following points:

1. Inspect the air transfer duct between the air cleaner and the engine to be sure all clamps are tight, all flange joints

are tight, and there are no cracks in the ducting.

2. Air cleaner mounting bolts and clamps must be tight to hold the air cleaner securely.

3. Check the dust cup to make sure it is sealing 360 around the air cleaner body.

4. Vacuator valve must be in place, not inverted or damaged, and free from obstruction.

5. Check for dents and damage to the air cleaner which could mean a leak.

6. Make sure all inlet accessories are free from obstructions and securely mounted.

7. Check pre-cleaner fins for plugging.

PAGE 110