TM 5-3805-296-10

0012

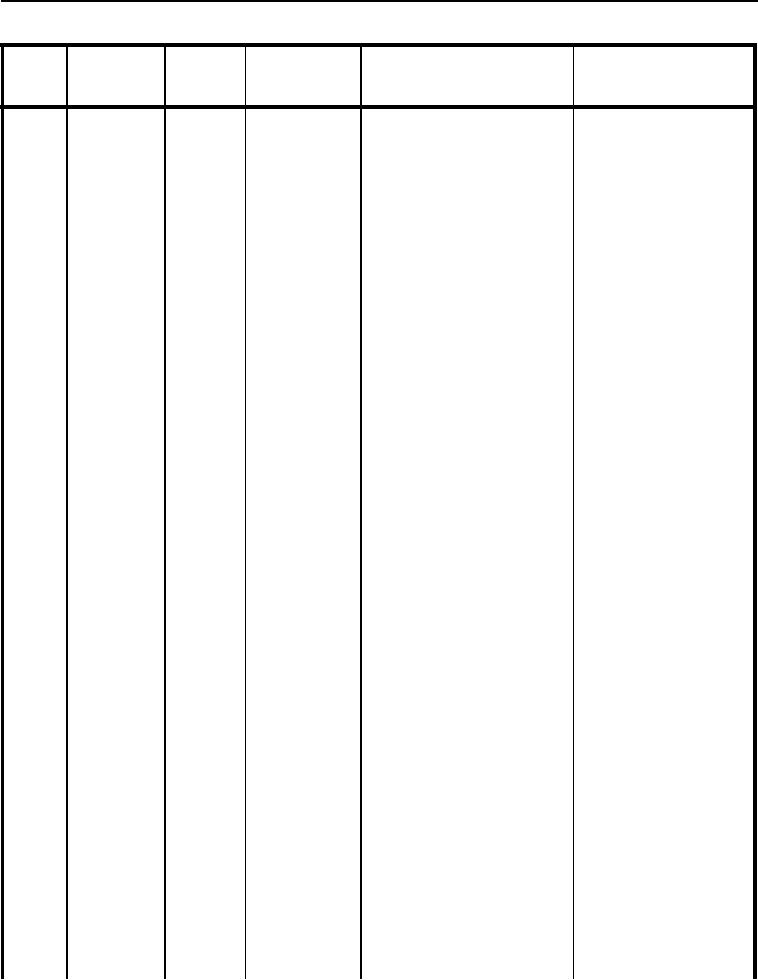

Table 1. Preventive Maintenance Checks and Services (PMCS) Continued.

ITEM TO BE

ITEM

MAN-

CHECKED OR

EQUIPMENT NOT

NO.

INTERVAL

HOURS

SERVICED

PROCEDURE

READY/AVAILABLE IF:

All Systems -

80

Every 250

g. Move machine and

Machine

(Cont.) Engine

continue to operate all

Exercise

Hours or

controls through full motion for

Monthly

30 minutes AFTER machine

systems have reached

operating temperature.

h. Stop machine and allow to

idle for five minutes.

i. Shut down engine.

j. Perform After operation

PMCS.

81

Every 250

a. Check for loose, missing,

Drive belt is loose,

Engine

frayed, or cracked drive belts.

missing, or damaged.

Hours or

b. Check for loose or

Pulley is damaged.

Monthly

damaged drive pulleys.

Machine moves with

Perform the following service

Service Brake

82

Every 250

brake test:

engine rpm less than

Test

Engine

1400 rpm.

Hours or

a. Test brakes on dry, level

Monthly

surface.

b. Ensure area around

machine is clear of all

personnel and obstacles.

c. Fasten seat belt before

testing brakes.

d. Ensure air system is at

operating pressure of 110

10 psi (758 69 kPa).

e. Raise bowl.

f. Apply service brakes and

release park brake.

g. With engine at idle and

service brakes applied, move

transmission shift lever to

forward speed position 2.

h. Gradually increase engine

rpm. Service brakes should

prevent machine movement

with engine running at 1,500

100 rpm.

0012-75