TM 5-3805-296-10

0012

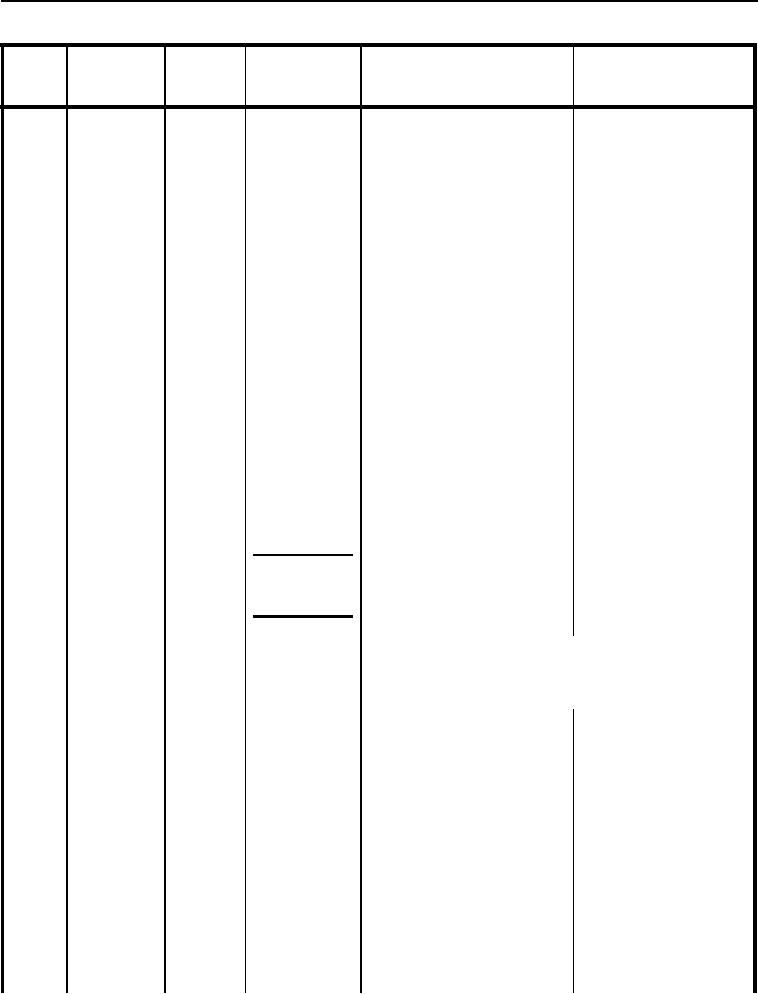

Table 1. Preventive Maintenance Checks and Services (PMCS) Continued.

ITEM TO BE

ITEM

MAN-

CHECKED OR

EQUIPMENT NOT

NO.

INTERVAL

HOURS

SERVICED

PROCEDURE

READY/AVAILABLE IF:

39

During

Scraper

Monitor bowl operations for

unusual noise or vibration

from apron, ejectors, and bowl

lift cylinders.

40

During

Overall

Be alert for evidence of fluid

Class III oil or hydraulic

Leakage

leakage.

leaks are evident. Any

fuel leak is evident.

41

During

Instrument

With machine fully warmed

Gauges indicate an

Panel

up, monitor warning lights and

abnormal reading.

gauges.

a. Engine coolant

temperature range should be

in the green range.

b. Torque converter oil

temperature range should be

in the green range.

c. Air system operating

pressure range should be in

the green range. (110 10 psi

(758 69 kPa if viewing digital

display).

Front and

Left Side

N OT E

Ensure machine is clean in order to facilitate

proper PMCS inspections.

Class III oil or hydraulic

42

After

Overall View

a. Check under machine for

leaks are evident. Any

evidence of fluid leakages

fuel leak is evident.

such as oil, coolant, fuel, or

hydraulic fluid.

b. Check machine for

Damaged or missing

damaged or missing

components that would

components (e.g., hitch pin,

impair operation is

belly pans) that would impair

evident.

operation.

Damage that would

43

After

Cab Exterior

a. Check for damage to

impair operation is

lights, windows, window

evident.

wipers, steps, grab handles,

fender, latches, and hinges.

0012-33